From the close cooperation between Deltar and seat and ball manufacturers comes Sixeal® usable, for example, in high-pressure ball valve applications.

Sixeal® offers numerous advantages for metal-to-metal applications.

Sixeal®, a kit consisting of a seat and ball coated with nickel silicon carbide NiSic, is born. Sixeal offers numerous advantages for metal-to-metal applications.

Corrosion resistance, high hardness, no end grinding, whole surface coating, elasticity ,lower cost, time saving.

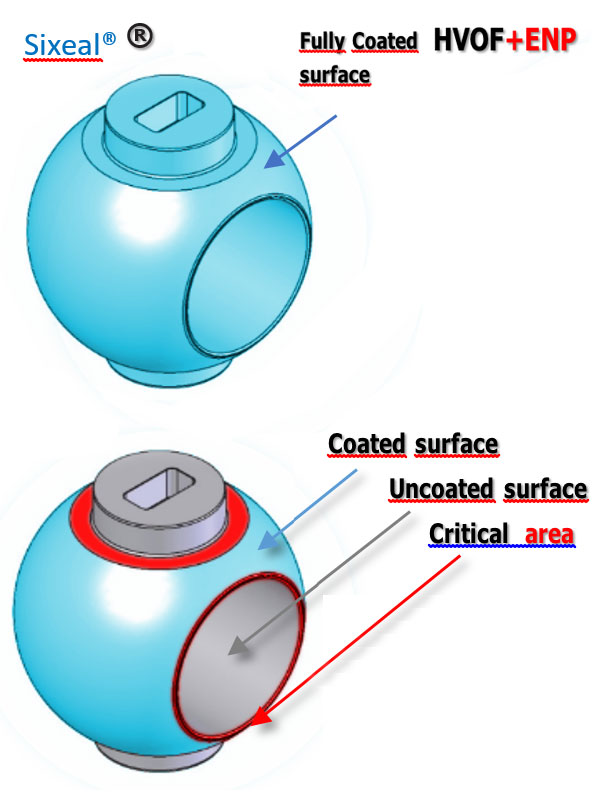

Sixeal® enables advantages on metal-to-metal applications in order to achieve the best valve performance; this treatment is the best performing and most reliable solution to achieve a fully coated surface.

This specific coating avoids critical areas by ensuring a drastic reduction in erosion resulting in excellent wear resistance .

With one treatment, the trim can be prepared for the corrosive and abrasive part of operation while allowing metal-to-metal sealing.

NiSic

Micro particles of silicon carbide are added into the ENP “bath” to achieve a nickel coating in which sub-particles are embedded evenly distributed throughout the treated surface. The result is a hard, homogeneous, strongly embedded coating element in a nickel matrix that combines the hardness properties of silicon and the chemical resistance of ENP.

Because the process is based on the same procedure used in chemical nickel plating, the thickness of the Sixeal® coating is kept the same over the entire coated surface. The typical surface hardness of Sixeal® reaches 1200 HV creating the best condition to easily reduce the roughness to 0.2 Ra on the entire ball surface and 0.1 Ra on the adapted area achieving a better torque level and consequently preserving the integrity of the kit.

The extreme hardness of the coating and the chemical resistance characteristics of the nickel protection allow A350 LF2 high-performance carbon steel to be used to achieve the best performance from -46 to 550°C while ensuring excellent chemical-physical and abrasion characteristics.

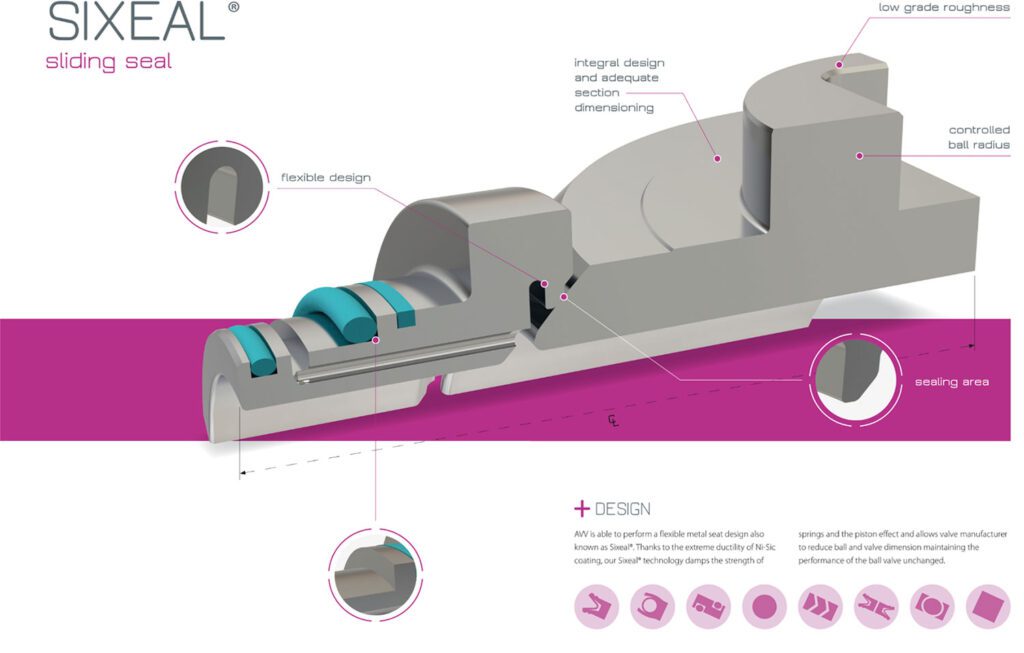

The characteristics of Sixeal® allow for a flexible metal-to-metal seat design .In fact, due to the extreme ductility of the Ni-Sic coating, this Sixeal® technology makes it possible to cushion the spring resistance, piston effect, and follow the elastic deformation of the ball and consequently allow the valve manufacturer to reduce the size of the ball and valve while maintaining the performance of the ball valve, which is also ideal in high-pressure ball valves

The lapping step, performed with cast iron ring and abrasive paste, is necessary to achieve centesimal sphericity. The next step is an adjustment between the sphere and the seats. The latter verified by 100% performance of the “Prussian blue” test. Improved performance of Ni-sic treatment is ensured by a second coupling stage, performed after Ni-Sic treatment. An airtight seal and proper roughness of the contact area ensure a final matching that is performed with different grades of diamond paste.

The process is supervised from the beginning of processing: starting with the prussian blue test, proceeding with a rigorous check on sphericity and circularity, going through a post lapping stage and finalizing with a 100% bubble test. Hardness, density, adhesion, thickness and corrosion tests are required as standards for surface treatment qualification.

The right combination of SIXEAL®, ball, and seat front and back seal makes a metal-to-metal kit suitable for all kinds of service: high temperature, cryogenic, “slurry” applications, H2S, quick-opening valves, high-pressure valves, and so on.

Bearings and Shafts: In mechanics, rotating shafts can slide against metal bearings, although in many modern cases composite materials or coatings are used to reduce friction and wear.

Gears: Sprockets in gears are a classic example of metal-to-metal contact, requiring adequate lubrication to reduce wear and overheating.

Pipe and fitting joints: In plumbing applications and piping systems, metal-to-metal joints are common to ensure the tightness and strength of the connection.

Valves: In both domestic and industrial settings, valves often employ metal sealing surfaces to regulate the flow of liquids or gases. These include the

high-pressure ball valves

Internal Combustion Engines: Components such as pistons, piston rings, cylinders, connecting rods, and other parts within the engine have metal-to-metal contacts, requiring high-performance lubricants.

Load-bearing Structures: In metal constructions, such as bridges or high-rise buildings, metal joints play a crucial role in load distribution and structural strength.

Surgical instruments: Many instruments used in surgery are made of metal and may have components that slide or rotate against each other.

Guides and Slides: In machinery such as lathes, milling machines, or machining centers, metal slides enable precise movement of axes.

Aerospace Components: Items such as joints, bolts, and mounts in aircraft or rockets often employ metal-to-metal couplings for their reliability and strength.

Braking Systems: Disc and drum brakes in vehicles and heavy machinery use metallic materials for friction generation and thus deceleration.

These applications demonstrate how metal-to-metal contact is critical in many fields, from traditional mechanics to high technology. Friction, wear, and lubrication management are key aspects in the design and maintenance of these systems.

Legal headquarters and Plant: Via F.lli Rosselli, 10

20068 Peschiera Borromeo (Mi)

REA MI 1547567 – C.F. and Register Milan companies n.12306070157

Share capital: € 10.200,00 i.v.- VAT 12306070157

Office phone. +39.02.55305101 – Fax +39.02.99990042

Plant: +39.02.55305457

info@deltar.it – deltar@pec.deltar.it

Mon – fri: 8:30 – 12:30 AM, 2:00 – 6:00 PM

Saturday and Sunday – CLOSED